Products

HANKOOK ADVANCED MATERIALS EXTRUDER

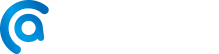

Graphite Extrusion Products

Synthetic Graphite Extrusions.

Synthetic graphite extrusions refer to cylindrical graphite blocks formed by mixing coke derived from coal and petroleum by-products with a high-carbon-yield binder, then extruding and heat-treating them at high temperatures (1000℃ to 3000℃).

Continuous extrusion through dies allows for high productivity, long length, and uniform cross-sectional shape.

With unmatched properties such as heat resistance, electrical and thermal conductivity, chemical resistance, low thermal expansion, and self-lubrication, these products are essential in high-temperature industries like steelmaking, semiconductors, and aerospace.

Main Product Categories

Core Technologies and Product Features

01.

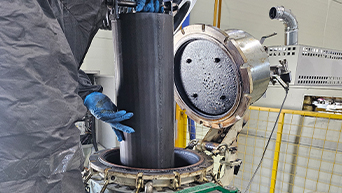

In-house development of a 1000MT-class graphite extruder for graphite extrusion

02.

Possesses know-how and technical data for pre- and post-processing

03.

Holds patents for graphite extrusion manufacturing technology

04.

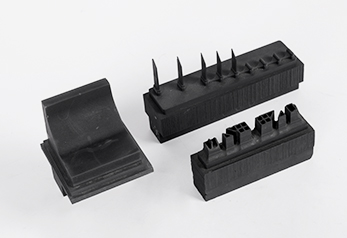

Superior oxidation resistance and process safety compared to competitor products

05.

Capable of producing graphite extrusions customized to client requirements

Production Process

Forming

PROCESS 01.

Crushing

Mixing & Kneading

Forming

Post-Processing

PROCESS 02.

Carbonization & Recabonization

Impregnation

Machining and Inspection

PROCESS 03.

Cutting

Machining

Inspection

Applications

Steel & Metallurgy

Graphite electrode rods, heaters, furnace linings, crucibles, etc.

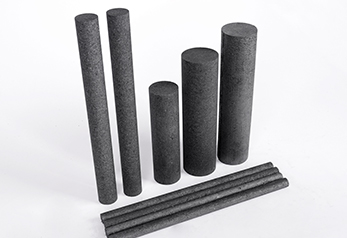

Machinery

EDM electrodes, sealing gaskets, etc.

Electronics & Semiconductors

Heat sinks, semiconductor heaters, wafer susceptors, etc.

Nuclear Power

Fusion reactor walls, neutron moderators, etc.

Chemical Industry

Corrosion-resistant containers, anode plates, etc.

Aerospace

Engine nozzles, thermal protection systems, etc.