Products

HANKOOK ADVANCED MATERIALS EXTRUDER

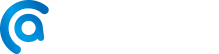

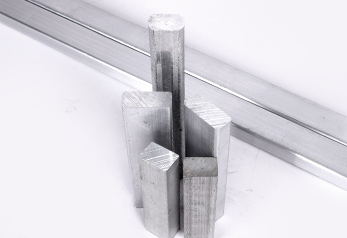

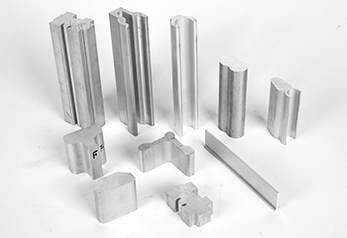

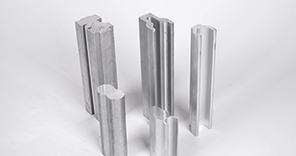

Aluminum Extrusion Products

Aluminum Extrusions.

Aluminum extrusions are made by heating aluminum alloy billets at high temperatures and extruding them through specially shaped dies to continuously form products of various shapes.

Depending on requirements, long aluminum extrusions with specific cross-sectional shapes can be manufactured, allowing for a wide range of applications.

With features such as corrosion resistance, low density, and high strength, aluminum extrusions are essential in modern industries such as transportation and aerospace, where lightweight materials are critical, as well as in marine and chemical industries requiring corrosion resistance.

Main Product Categories

Production Materials

Aluminum alloy shaped products(excluding pipes)

10xx 20xx 30xx 40xx 60xx 70xx

Aluminum pipes

10xx 30xx 60xx 7005(7N01)

Core Technologies and Product Features

01.

Equipped with a 2200MT-class extruder optimized for forming small-diameter products using high-strength duralumin materials

02.

Possesses extrusion die manufacturing technology that maximizes quality and productivity

03.

Quality control aimed at customer satisfaction

04.

Capable of responding to all temper types

05.

Capable of extruding various aluminum alloy materials

06.

Able to manufacture extrusions in shapes requested by client companies

Production Process

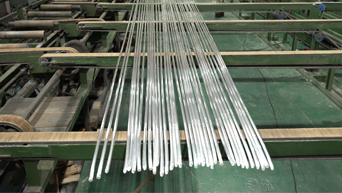

Extrusion

PROCESS 01.

Billet cutting

Extrusion

Primary cutting

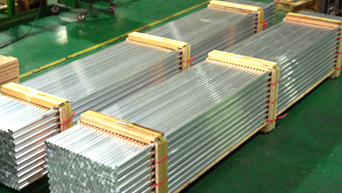

Post-Processing

PROCESS 02.

Stretching

Front/rear cutting

Packaging

Heat Treatment and Inspection

PROCESS 03.

Solution heat treatment

Aging

Final inspection